Flexography

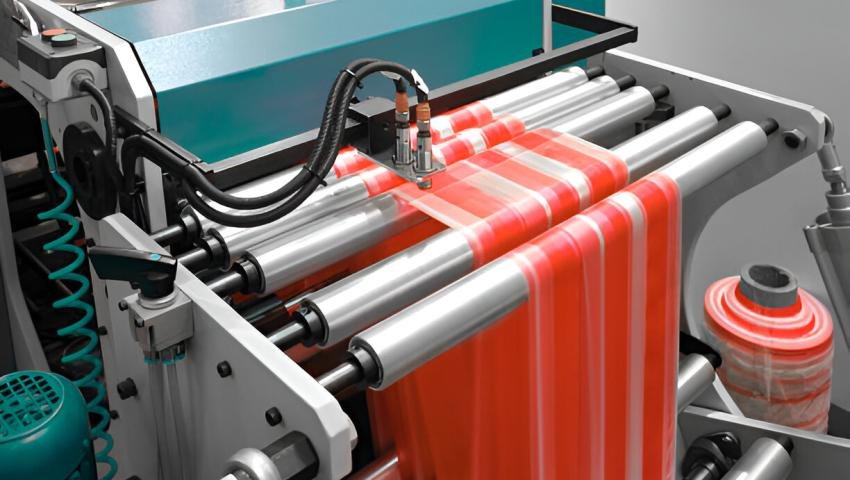

Our Flexography is a high-speed printing process that uses flexible printing plates to transfer ink onto a variety of substrates. commonly used for packaging, labels, and other materials that require continuous printing over large surfaces. Flexography is known for its ability to print on almost any material, plastic, metal, cellophane, and paper, making it an ideal choice for packaging and label.

Our Flexography Services uses flexible relief plates made from rubber or photopolymer.

Here’s how it works in detail:

- Plate Creation

- Ink Application

- Printing

- Drying

- Plate Creation: A flexible plate is created with raised images and text that will transfer ink to the material.

- Ink Application: The plate is coated with fast-drying ink, which is then transferred to the material as it moves through the printing press.

- Printing: The inked plate comes into direct contact with the substrate (such as paper or plastic), transferring the image or text.

- Drying: Flexo inks are quick-drying, which allows the process to run at high speeds. The printed substrate passes through drying units to cure the ink almost instantly.

- High-Speed Production: Flexography is one of the fastest printing processes, making it ideal for large print runs, especially in packaging.

- Versatility: It can print on almost any material, including non-porous surfaces like plastics and metals.

- Cost-Effective for Long Runs: While there is an upfront cost to create the plates, flexography becomes highly economical for high-volume production runs.

- Wide Range of Inks: Flexo can use various ink types, including water-based, solvent-based, and UV-curable inks, allowing for specialized finishes.

- Consistent Quality: It provides excellent repeatability, ensuring that every item in a large batch has the same quality.

- Packaging (Boxes, Cartons, Plastic Bags)

- Labels (Food, Beverages, and Product Labels)

- Corrugated Cardboard

- Flexible Packaging (Pouches, Wrappers)

- Envelopes

- Gift Wrap

- Tissue Paper

Best For:

- Large-scale production of packaging and labels

- Printing on various materials, including flexible and non-porous surfaces

- High-speed production runs where quick drying is essential

Our Flexography Services is an ideal solution for industries that need high-volume, continuous printing on a wide variety of materials, particularly in the packaging and labeling sectors. Its speed, versatility, and efficiency make it a go-to option for brands looking to produce large quantities quickly and consistently.